Abstract

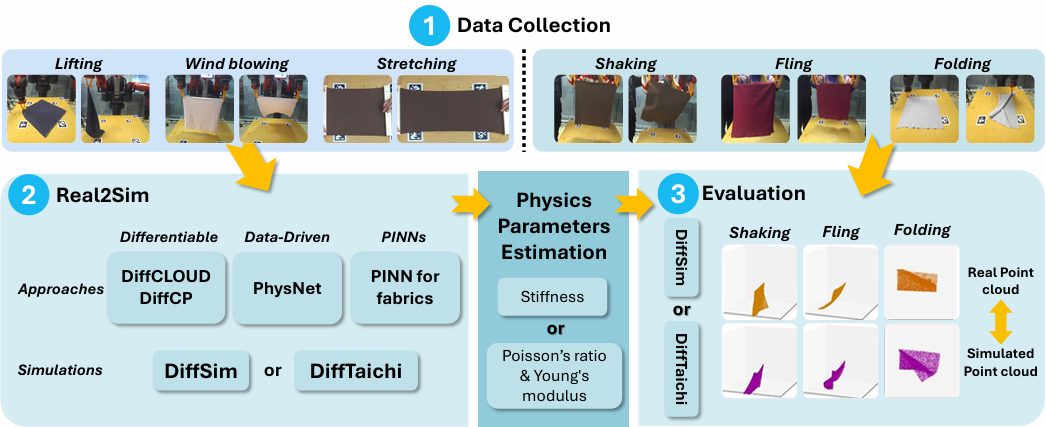

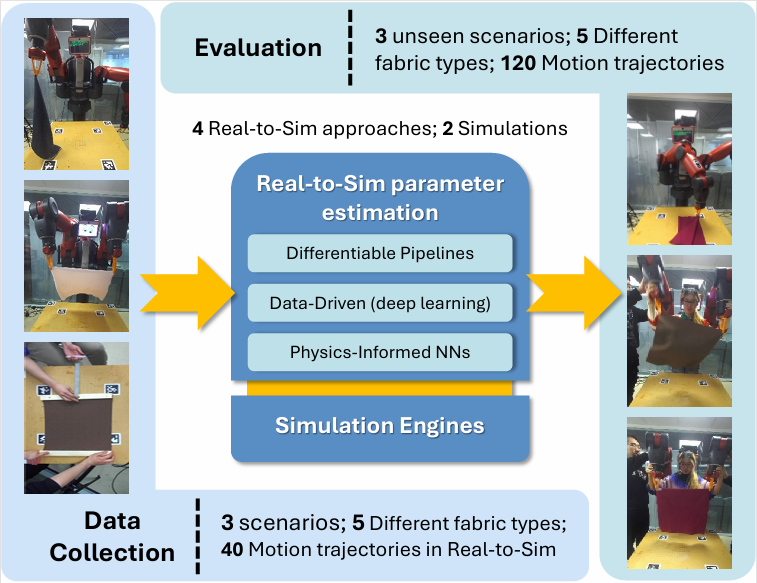

The Sim2Real gap remains a significant challenge in fabric manipulation policy training in simulation, not only because of the simulator's mechanism performance, but also largely because simulated fabrics with default physics parameters behave differently than real fabrics when manipulated along identical action trajectories by handles. Previous work has explored various real2sim methods for estimating fabric physical parameters, but these approaches typically focus on training within a single scenario. To address the lack of evaluation assessing the accuracy of physical parameters estimated by current Real2Sim methods in predicting fabric behavior across unseen scenarios, we propose a comprehensive Real2Sim2Real study pipeline that evaluates the physical meaningfulness of estimated parameters by measuring the behavioral differences between simulated and real fabrics under the same manipulation trajectories in different scenarios.

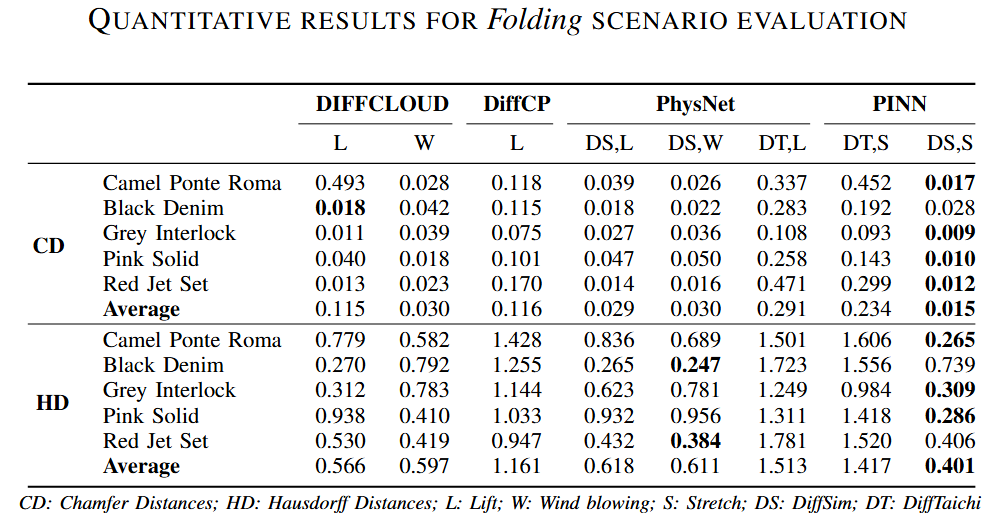

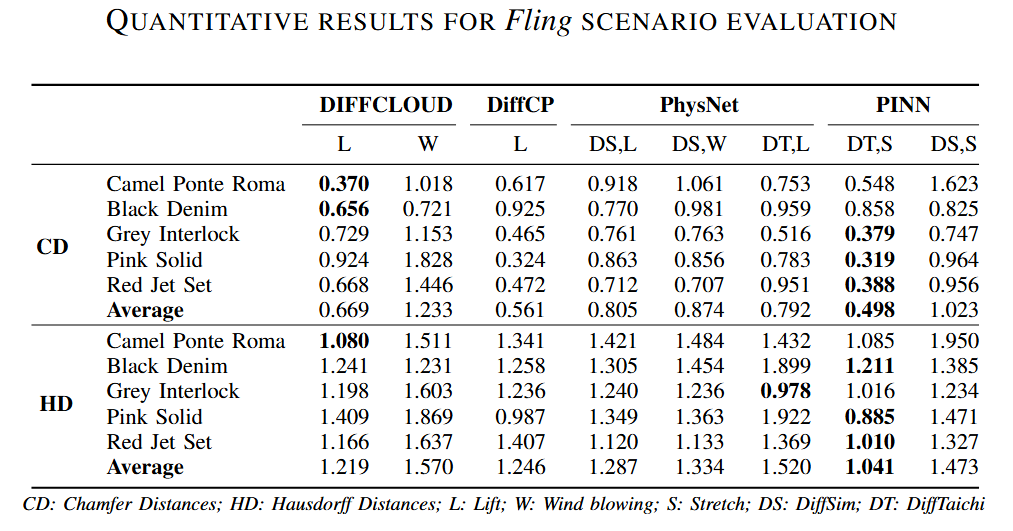

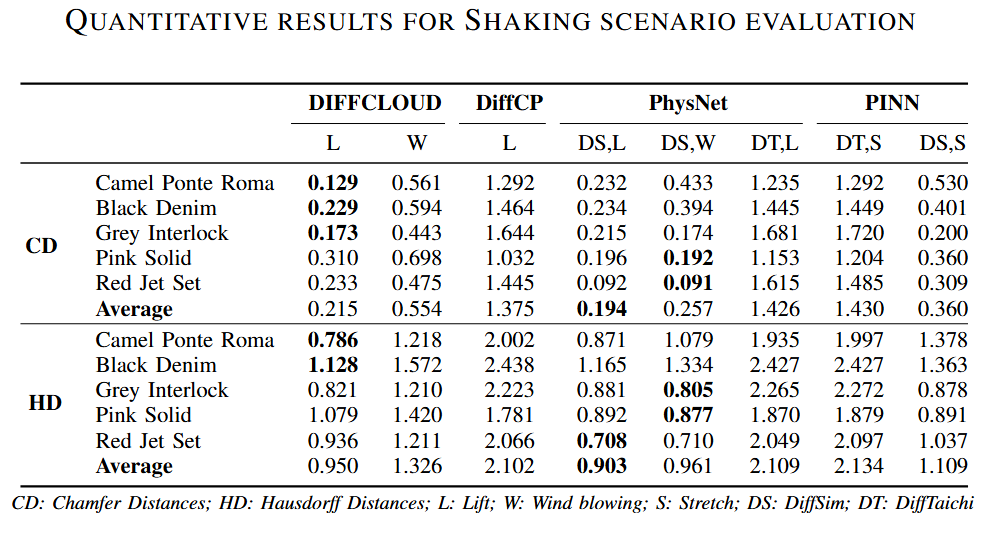

This paper presents a rigorous evaluation of Real-to-Sim parameter estimation approaches for fabric manipulation in robotics. The study systematically assesses three state-of-the-art approaches, namely two differential pipelines and a data-driven approach. We also devise a novel physics-informed neural network approach for physics parameter estimation. These approaches are interfaced with two simulations across multiple Real-to-Sim scenarios, wind blowing, and stretching for five different fabric types and evaluated on three unseen scenarios folding, fling, and shaking. We found that the simulation engines and the choice of Real-to-Sim approaches significantly impact fabric manipulation performance in our evaluation scenarios. Moreover, PINN observes superior performance in quasi-static tasks but shows limitations in dynamic scenarios.